Precursor: The work I do at Engineered To Slide is only a small portion of what is required for these projects, the results remain solely the product of Nigel’s hard work and years of experience, I’m just called in to help on the CAD side of things. None of this would be possible without the opportunities and teachings Nigel has offered in the last few years.

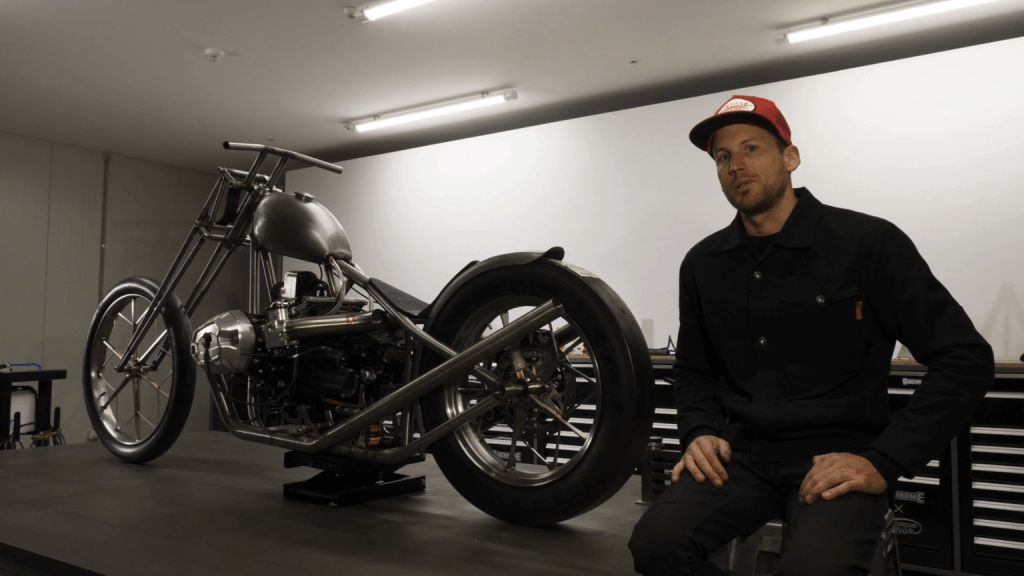

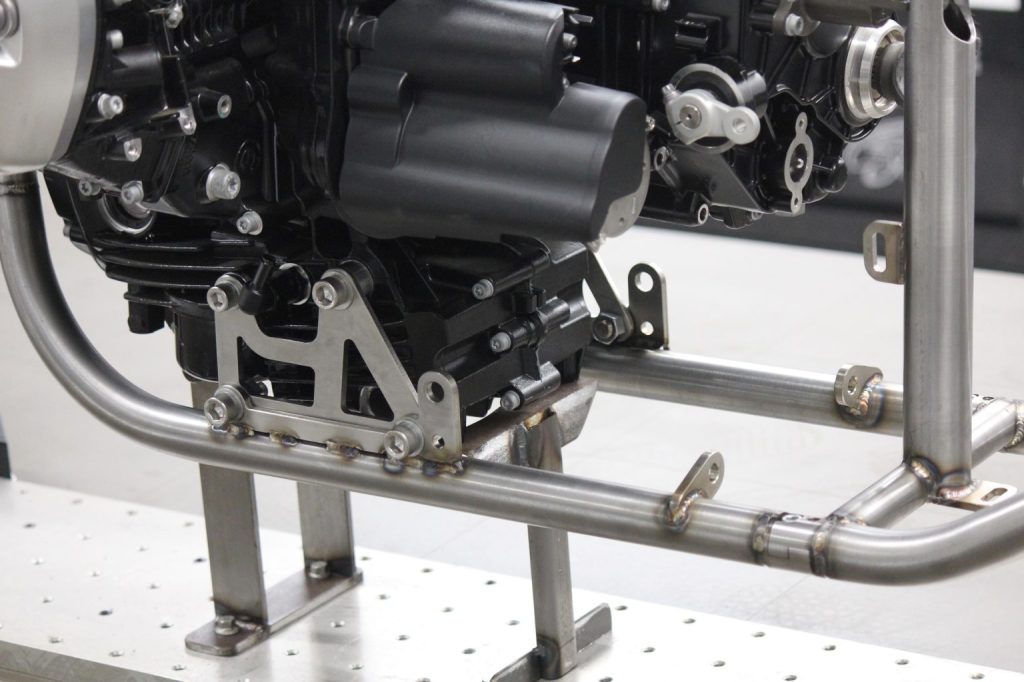

Back in early 2019 Nigel was asked by BMW Motorrad to build a chopper around their RnineT engine platform which is a 1170cc horizontally opposed twin cylinder (boxer). I was in the second year of my Mechanical Engineering (Honours) degree at Deakin University when I had scored myself some work with Nigel, who had just moved his business onto the campus into a workshop at Manufutures. I used to go in to ETS roughly once a week and spend some time drawing up parts in CAD for the BMW chopper and an electric bike project. It started off with small laser cut parts such as engine mounts.

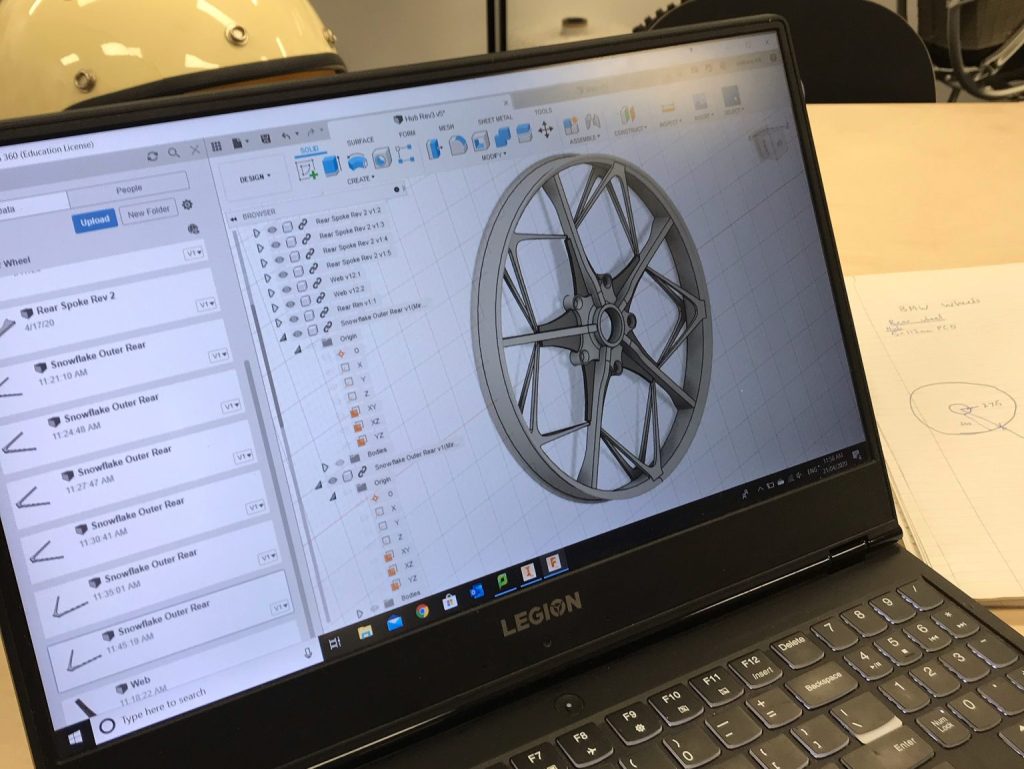

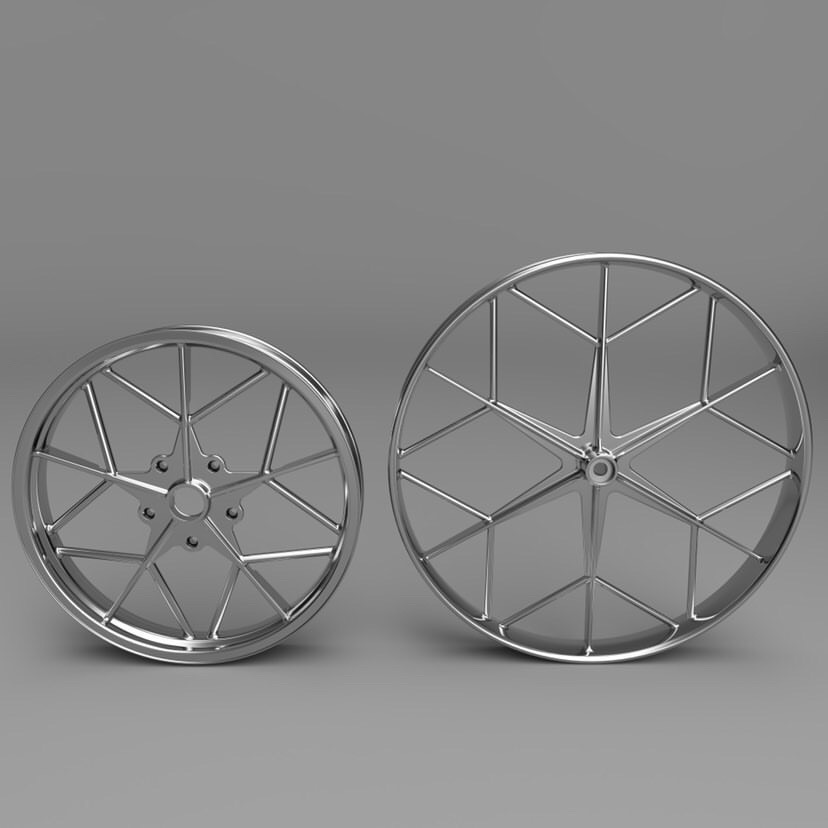

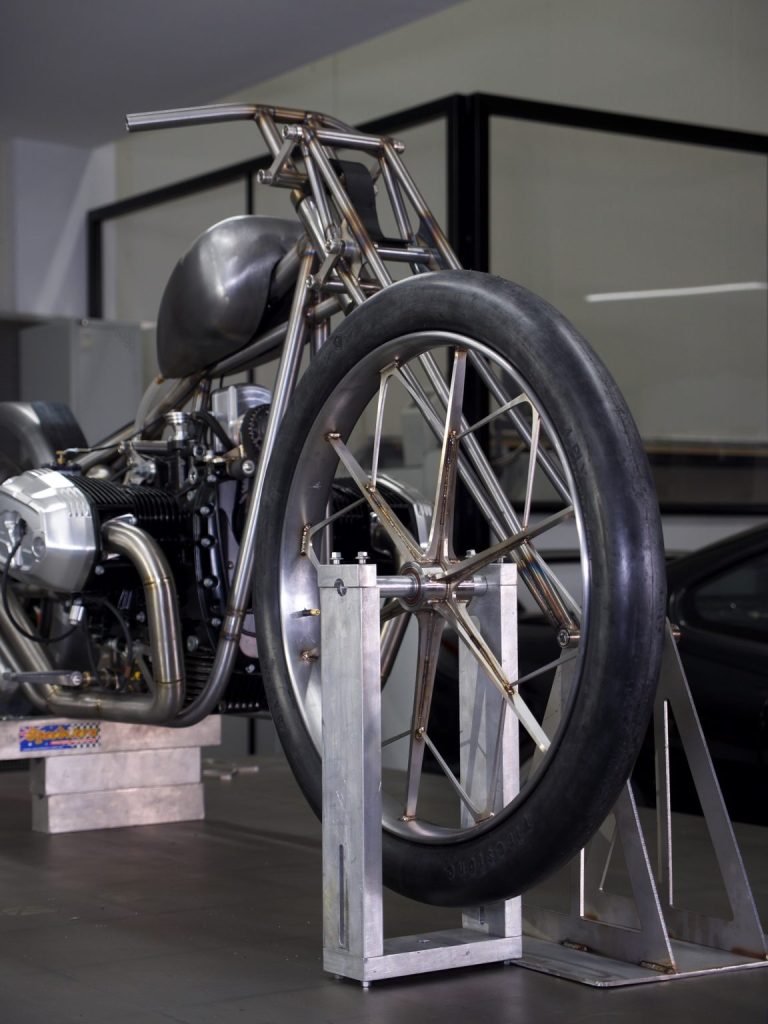

As the project moved along Nigel started dreaming up all sorts of crazy ideas about wheel designs. When he told me he wanted to make his own set of wheels I thought he was mad, then he told me he wanted me to model them up in CAD. Eventually he tracked down an old cast snowflake rim that was similar to what he had in mind. I went to work on designing up a snowflake wheel set to be CNC machined.

During the process of designing this up, Nigel also had a friend do some renders of his own take on the wheel set (@cornerstone.mfg) which are shown below. These looked great and helped guide our decision making in design, we just had to figure out best how to build them.

After the CNC wheel designs were done we spoke to some people about getting them machined, it was going to cost $12,000 which was just too high to justify.

After sitting on that idea for some time Nigel had an idea; laser cut each piece and TIG weld them together. This meant we had some big changes to make to the CAD model to accommodate the new fabrication method. I began piecing together an assembly of 2D parts to form the spokes and snowflake pattern. Nigel bought two outer rim blanks and I modelled a couple of hubs to be CNC machined.

Eventually we came to a final design and the parts were sent off for laser cutting/machining:

Watching these wheels come to life through the power of Nigel and his welder was great. From what I can remember, this was the first cool thing I’d designed at ETS that wasn’t just a small tab or engine mount. I was stoked, and still am. I’m very greatful for the opportunities Nigel provided throughout my studies. This project was a real testament to his fabrication skills and creativity.

Read more about the BMW Chopper wheel build here.