Nigel at Engineered To Slide has a Nissan S15 that he’s turning into a race/track car. While working on the car he’s been filming every step and producing online courses for ETSFab. Nigel’s built plenty of roll cages before, but this time he wanted to show some of the process involved in doing it professionally and getting it FIA approved. Luckily, Deakin University has a Creaform 3D scanner they were happy to lend us. I 3D scanned the car’s interior and designed a roll cage which we could then do FEA (Finite Element Analysis) on.

Everything in the car had to be stripped out, only the bare metal shell left. I began researching 3D scanners and practiced on a few small parts of the car, I found that black reflective surfaces are very hard to scan… The S15 is gloss black – unlucky!

We required a white, dust-like spray to cover the painted black surface to prevent the light being absorbed into the black paint, this meant the light was reflected for the scanner to read.

The scanner uses small sticker dots to keep track of where it is at any point. I spent a lot of time crawling around in the car putting in these dots, all spaced randomly about 6 inches apart. Then I used the spray to dust the most glossy black surfaces, under the seats and carpet was mostly primer which scans really well.

I began scanning from the middle of the car floor (trans tunnel) to the outside, then up the pillars and across the roof. This will ensure the scan is accurate and doesn’t begin to warp/walk around. I must say it will be a lot easier next time I scan a car, I learnt a lot about how the scanner works and the techniques used to make the process efficient.

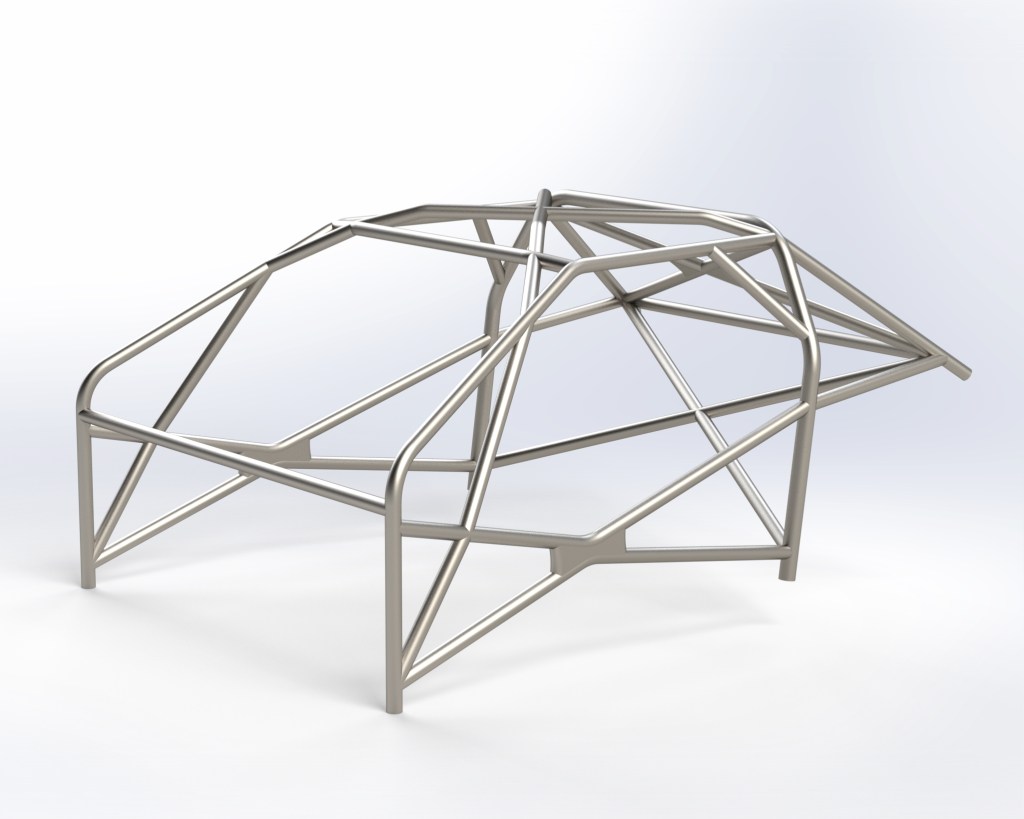

From here I exported the file to a CAD (Computer Aided Design) program and began laying out the roll cage inside the 3D scanned body.

Initially we wanted to use a special type of automotive high carbon steel for the cage but later found out that it is treated the same as Chromoly in the racing regulations. This means our cage would have had to adhere to the minimum tube sizes of Chromoly even though the new material would be 2-3 times stronger.

To use Chromoly or our other steel choice the cage would’ve had to go through FEA testing and be FIA approved, this costs around $4,000. In the end we opted for Mild Steel as the material choice as we could then get the cage MA (CAMS) affiliated which is cheaper (~$200). The weight difference between the initial design and the Mild Steel design is around 15kg due to the thinner tube walls, There was about the same weight of sound deadening in the car which we chipped out and removed for free. The $4000 for a 15kg gain just wasn’t worth it. Hopefully the rules can be adjusted to freely allow for materials other than Chromoly and Mild Steel in the future.

After the design was finished I completed some FEA testing using New Zealand’s governing body for motorsport regulations, this is because Motorsport Australia do not specify any force loads, they only allow to you design it a specific way that they’ve deemed safe (called schedule J). The FIA also doesn’t specify any loads, instead you must send your design to be approved by their affiliated companies, that’s the $4000 I mentioned before. The cage passed the FEA tests I did and we considered the design work finished. Nigel then commenced the process of fabricating the cage and filming it for his course. We had some hoops to jump through with cost and regulations but in the end I’m pleased with the roll cage design and can’t wait to see the car out on track!

Images of car and roll cage fabrication supplied by Nigel Petrie (Engineered To Slide)